Recipe Management for Liquid Processing

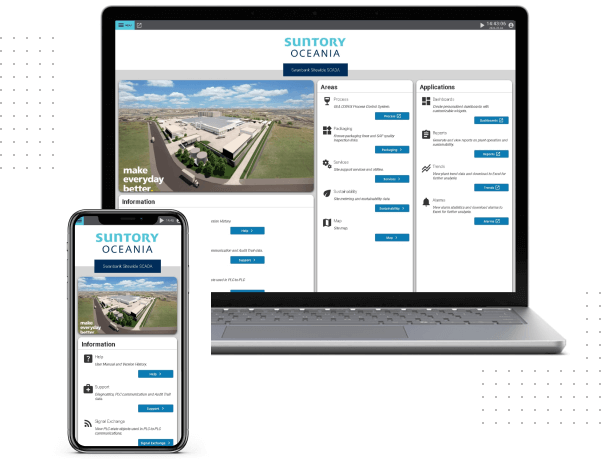

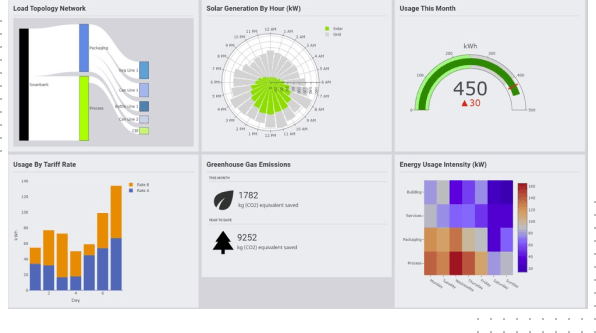

Discover the difference with CentricPA’s commitment to your plant’s success, developing turnkey solutions to revolutionise manufacturing.

Process manufacturers depend on their automation systems for accurate and repeatable mixing of raw ingredients to produce in-spec finished products. Variations in raw material properties (concentration, density, seasonal variation etc.) are unavoidable, but can present significant challenges to repeatable automation resulting in finished product quality variances.

Similarly, in the continuously evolving FMCG market, manufacturers must be able to quickly react to consumer preference with the agility to produce new brands and formulations.

Contact our engineering team

Recipe based Automation

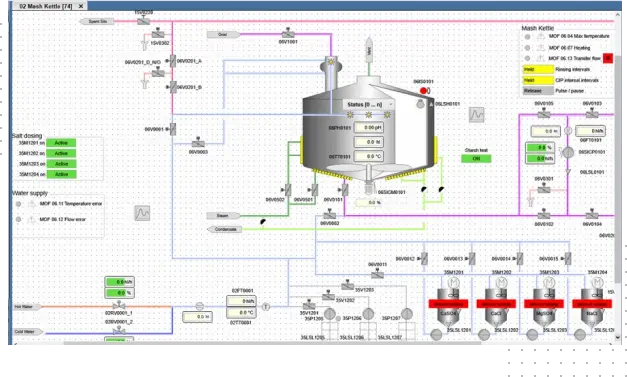

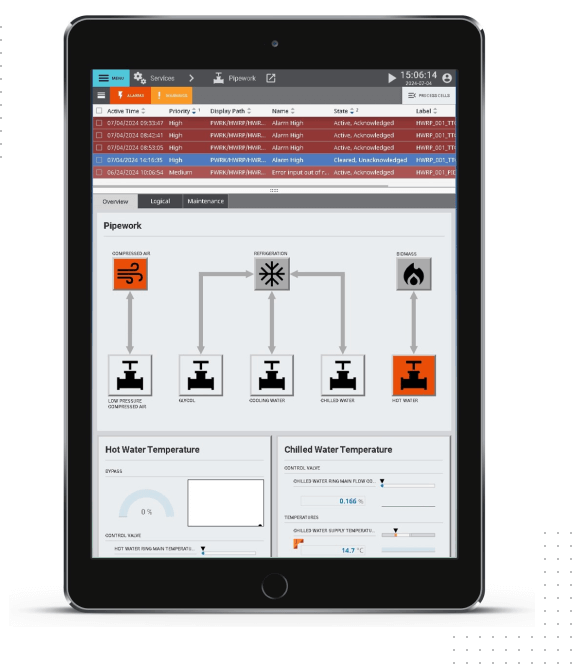

Using the Recipe Management module of Centric PA’s MES suite, Equipment Phases are grouped into Batch Procedures, which control & orchestrate the process on the plant floor. Batch procedures are parameterized by recipes, which define required setpoints for brand/product specific parameters (quantities, dosing rates, processing times etc.).

These recipes can be viewed, created, and modified (with full audit trail) from a web browser, or mobile application, and once releases are immediately available to operators of the SCADA application.

Designing for Flexibility

Centric PA works closely with our customers during preliminary designs to ensure plant equipment is tagged and logically grouped to align with ISA-88 conventions. This often-overlooked step ensures that Process Descriptions can be efficiently translated into modular, class based automation – which reduces the amount of PLC code which must be written, tested and validated, saving the customer capital, and minimizing commissioning windows and risk.

This also provides a solid foundation for batch-based manufacturing through leveraging Centric PA’s suite of recipe management and MES modules.

Efficient Implementation

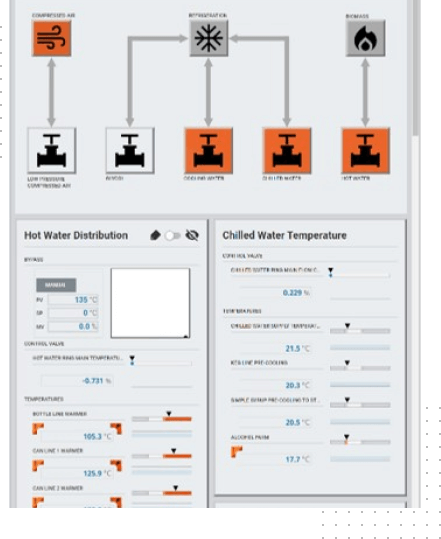

CentricPA leverages a software library of standard modules for controlling process equipment (Valves, VSD Motors, Instruments, PID Controllers, Phases etc.) and turning a customers’ process operation into a state-of-the-art plant. This approach provides the customer with a feature-rich automation system ‘out of the box’, with components that have been field tested across dozens of installations.

Application Example: ARTD Blending Plant

Centric PA developed a flexible, recipe-based automation system for a new Alcohol blending plant, to service an existing beverage bottler.

The recipe system specifies nominal quantities of Alcohol (LAL), sugar mass (kg), and Water for each product base, as well as minimum and maximum batch sizes. Via instrumentation, the system automatically accounts for variations in raw material concentration (ABV%, Simple Syrup Brix) and adjusts nominal setpoints accordingly. The flow rates of each ingredient stream are dynamically controlled during the transfer to maintain maximum throughput, whilst maintaining a blended ABV of <24%, for transfer outside of the hazardous area.

Ignition SCADA provides visualization, and Centric PA’s MES modules provide Recipe Management, CIP Analysis, and Product Genealogy.

Revolutionise your manufacturing processes with tailored solutions

Contact us today to explore how CentricPA can tailor process automation

solutions to suit you. One of our consultants will be in touch to discuss making

your production more agile, efficient, and sustainable.