Dairy Industry Automation

Intuitive systems providing flexibility and efficiency for producing high value product.Supporting The Dairy Industry

Manufacturing excellence for dairy companies

At CentricPA, we understand the unique challenges faced by Australia’s third largest rural industry, dairy. Our commitment to manufacturing excellence for dairy companies is rooted in our deep industry expertise, including the development of S88/S95 batching and recipe management systems. We specialise in tailored automation control, fostering seamless system integration, and harnessing the power of digitalisation. We empower dairy producers to enhance their production efficiency and quality, ensuring a sustainable future and a competitive edge.

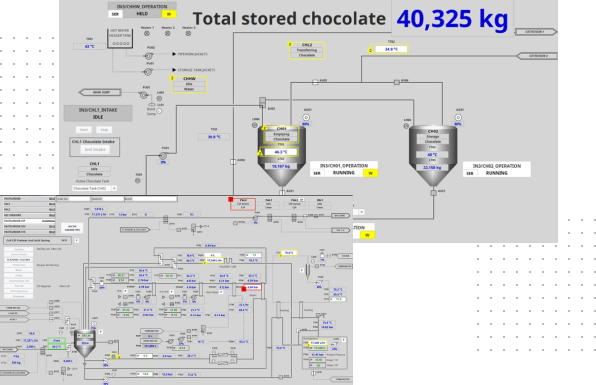

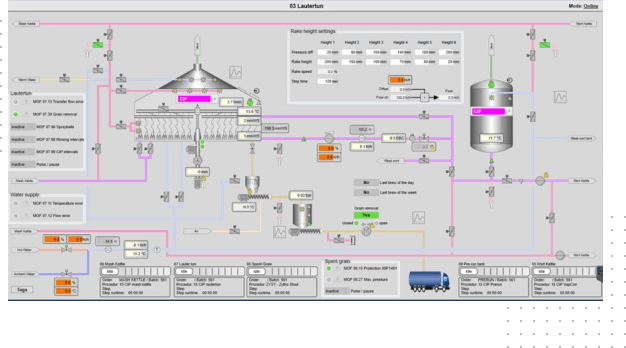

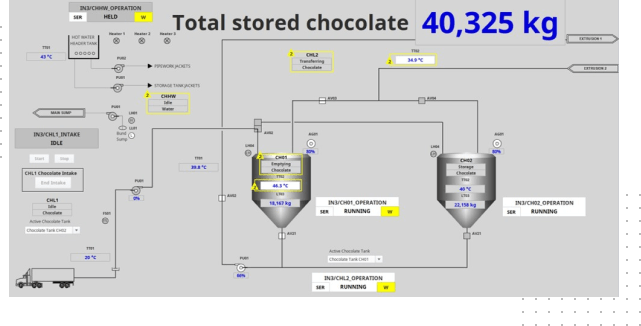

Process Automation

We apply S88/S95 standards and utilise the latest UI/UX to create automation control systems that support data-driven decision making on the plant floor.

Expert Digitalisation

Data is the DNA of the modern dairy industry. Our world-class batching and MES solutions help you contextualise your data and optimise your assets, all with the best cyber-security.

Contact our engineering team

Excellence in Every Batch

Expertise in batch S88/S95

CentricPA’s batch S88/S95 expertise can shine in the dairy industry. Dairy products require stringent quality standards. With our structured batching PLC, SCADA, and MES frameworks, you can guarantee top-notch quality for products like milk, cheese, and yoghurt. With a ‘build once, deploy many’ philosophy, we’ve created a library of tested modules to ensure scalable production and consistent implementation, whether you’re processing milk or crafting artisanal cheeses.

Our customer successes include major Australian and international dairy manufacturers. With our precise batch control, you can trust that each product meets your high standards, helping you develop customer satisfaction and brand loyalty. With our solutions, you can deliver excellence in every batch.

ABOUT Us

There are many variations of passages of Lorem Ipsum available

Year on year we build our knowledge, invest in our people and continue to embrace new technology. This has lead us to being an industry leader in the development and delivery of world class S88/S95 batching systems and MES solutions. All developed in house to be best in class.

Year on year we build our knowledge, invest in our people and continue to embrace new technology. This has lead us to being an industry leader in the development and delivery of world class S88/S95 batching systems and MES solutions. All developed in house to be best in class.

Produce More With Less

Tailored system design

Efficiency is paramount in the dairy industry. CentricPA’s system design can help you optimise your quality and efficiency at every step of the manufacturing process. We consider the unique challenges of dairy processing and also take into account the unique aspects of your plant, including legacy equipment.

Our dedication to tailored system design ensures you can produce more with less. Whatever kind of dairy you process, our systems are designed with scalability and efficiency in mind. Our solutions provide the foundation for your dairy operations to thrive and adapt to evolving market demands.

Adapt And Thrive In An Instant

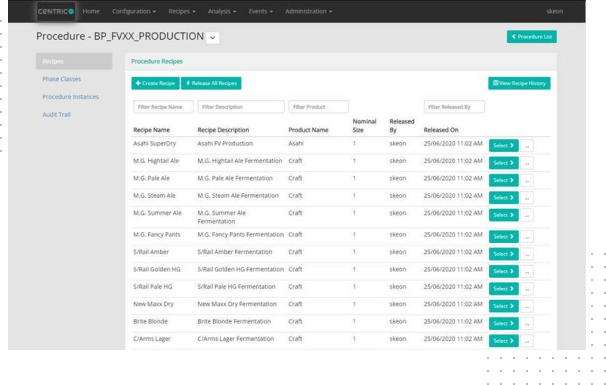

Recipe management solutions

Recipe management is at the heart of the dairy industry, and we can help you excel. Our recipe management systems empower dairy producers to create and modify recipes for various products, from milk and yoghurt to cheese. With a focus on accuracy and efficiency, our systems can help you deliver consistent product quality and rapidly change your recipes to meet market demands.

Built on open-source software, our systems can be tailored to your plant to help you achieve the perfect balance of ingredients. They are designed for accuracy, flexibility, and error-free results, providing you with the tools you need to adapt and thrive.

Why CentricPA?

Why CentricPA is your go-to process automation engineer in the dairy industry.

Dairy Expertise

With deeply rooted expertise in the dairy industry, we can provide the perfect tailored solutions for your business.

PLC & SCADA Systems

We deliver solutions that help you optimise your operations for efficiency and quality, ensuring you can compete in this fast-moving industry.

Increased Cybersecurity

Keep your plant secure with increased cybersecurity measures as we focus on protecting your data and equipment at all times.

Track and Trace

Get real-time visibility over your products and ingredients, ensuring quality and safety every step of the way and simplifying recalls.

Innovative UI/UX

Our systems are designed with the end user in mind, simplifying the process for your staff on the plant floor and enhancing data-driven decision-making.

Easy Upgrades

We make it easy to upgrade legacy systems while keeping what’s important to you, implementing modern, scalable solutions that grow along with you.

Our FAQs

Our most frequently asked questions.

Our deep knowledge of the dairy industry ensures we can engineer tailored digital solutions that genuinely help your plant. Whether your goal is to increase efficiency and traceability or to improve quality, we use our industry expertise and forward-thinking philosophy to produce a system that suits you.

Track and trace solutions provide real-time visibility into product processing. It can help you ensure product quality and safety. If you ever need to do a recall, our systems help you see exactly which products are affected. Plus, with exceptional genealogy tracking, you can see which ingredients and products to use first.

Automation refers to the process of making actions automatic. In the dairy industry, automation can help plants increase their throughput and grow their bottom line. Automated systems can handle everything from processing milk and packaging products to quality control and logistics. Not to mention the way process automation improves data handling, improving decision-making on the plant floor. Essentially, all modern plants need some kind of automation to improve their efficiency and stay competitive.

We prioritise cybersecurity in our process automation, protecting your operation. Our comprehensive approach safeguards data, processes, and equipment, ensuring you stay secure both during the transition and after.

Yes, our solutions are designed with scalability in mind. We make upgrades easy and minimise disruptions to your dairy operations during the transfer, ensuring seamless integration of all new technologies and processes.

Technology should, above all else, be usable. We design process automation systems with the end user in mind, with innovative UI and UX that provide help rather than hindering your workers. The systems collect data, while the UI/UX delivers it in a way that’s easy to understand and take action. As a result, your plant can be more efficient and informed.