Brewing Industry Automation

Engineering for consistent aroma, colour, bitterness and flavour.Empowering Brewers

Here’s why brewers work with CentricPA

With a proven track record of successful projects for the largest breweries in Australia and New Zealand, CentricPA has played a pivotal role in empowering brewers. Our projects include brewhouse upgrades, automated cellars, filtration and blending plants with full batching and traceability systems, and more. We empower our brewing customers to create consistent and repeatable processes, tailored around your unique needs.

Recipe Management Systems

Create, modify, and optimise your recipes for consistent brews and quality control even when your raw ingredients change.

Batching S88/S95 Standards

Our proficiency in international standards for PLC, SCADA, and MES solutions ensures structured, high quality every time.

Contact our engineering team

Make Each Batch a Masterpiece

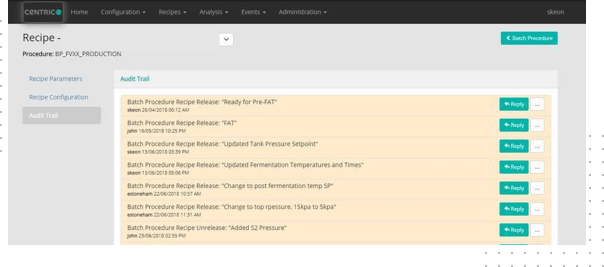

Recipe management for brewing

In the brewing industry, precision is paramount. CentricPA can help you manage your recipes easier than ever before, empowering brewers to craft consistent and high-quality brews. With automated recipe management systems that allow you to integrate with an MES and provide efficient, error-free results, you can combine your ingredients in the perfect balance.

Our solutions allow you to create, modify, and optimise recipes with ease, guaranteeing each batch is a masterpiece that’s consistent in flavour and quality. Plus, there are no ongoing licensing costs. We understand that every brewer’s creation is unique, and our solutions provide the tools for you to maintain your character while ensuring high quality in every batch.

ABOUT Us

There are many variations of passages of Lorem Ipsum available

Year on year we build our knowledge, invest in our people and continue to embrace new technology. This has lead us to being an industry leader in the development and delivery of world class S88/S95 batching systems and MES solutions. All developed in house to be best in class.

Year on year we build our knowledge, invest in our people and continue to embrace new technology. This has lead us to being an industry leader in the development and delivery of world class S88/S95 batching systems and MES solutions. All developed in house to be best in class.

Improve Product Quality And Safety

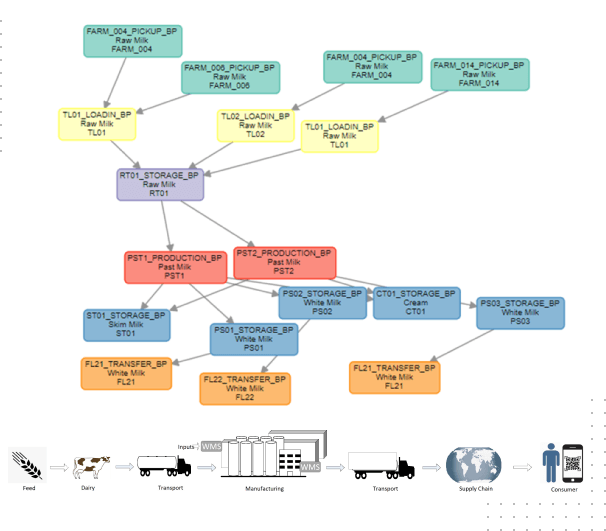

Track and trace solutions

Product quality and safety are some of the most important factors to consider as a brewer. Our track and trace solutions provide real-time visibility into product processing, ensuring higher quality and improved safety every time. These solutions enable efficient recalls when necessary, while our genealogy helps you see which products and ingredients to use first.

Our track and trace solutions empower brewers to maintain the highest standards. As a result, you can improve customer confidence and meet all the necessary requirements for safety.

Quality And Efficiency Together

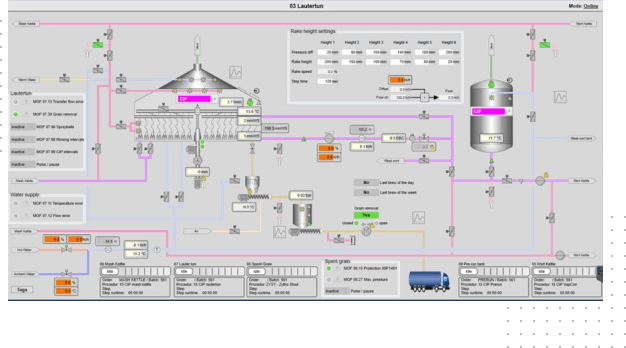

Batching S88/S95 expertise

CentricPA’s engineers have expert proficiency in batching S88/S95 standards. We deliver structured PLC, SCADA, and MES solutions that ensure consistent brew quality and plant efficiency. Our focus is on helping you deliver products that are consistent from a brewery that’s efficient, ensuring your operations are streamlined.

With our ‘build once, deploy many’ philosophy, we can build a system around you through tried-and-tested modules that have helped many brewers before. Whatever you need, we can help you grow, ensuring that efficiency and quality go hand in hand.

Why CentricPA?

Here’s why you should choose CentricPA as your process automation partner in brewing.

Brewing Expertise

We have brewing expertise with a proven track record in delivering successful projects for major breweries.

MIS/MES

Connect brewery processes and information with MES for real-time workflow visibility and process optimisation.

Tailored System Design

Get an automation system designed around your brewery, enhancing your efficiency while meeting your precise needs.

Innovative UI/UX

Simplify complex brewing processes with data-driven decision making, thanks to UI/UX that facilitates the use of data.

Hybrid Cloud Connectivity

Bring your brewery into the future with cloud connectivity from a private 4G network, including secure data management.

Future-Oriented

Stay competitive and adaptable with systems designed to scale along with you, ensuring you’re never left behind.

Our FAQs

Our most frequently asked questions.

We bring a wealth of industry knowledge to our process automation systems, enhancing your brewery’s operations to ensure consistent, high-quality products that will impress your customers and strengthen your brand. We’ve worked with some of Australia and New Zealand’s best breweries, giving us the experience we need to deliver the perfect solutions.

Harvesting data is one thing, but using it is another. We design process automation systems with the end user in mind. As a result, your plant staff can interpret and utilise the data you collect with ease, ensuring you can make data-informed decisions in real time.

By integrating MIS/MES, we provide breweries with real-time workflow visibility, flexibility, and actionable insights into optimising their operations. This helps them to increase overall productivity and profitability.

Brewing is changing all the time. New technologies in this arena include water recycling systems and flow meters. However, process automation systems are another way breweries are preparing for the future. With automated processes and hybrid cloud connectivity, breweries can become more efficient now and set themselves up for the future.

Our tailored systems use a ‘build once, deploy many’ philosophy. We create tailor-made solutions using tried-and-tested modules to develop a process automation solution that suits your needs, also in accordance with S88/S95 design standards.

At CentricPA, we are experts in process automation. Automation helps to make your manufacturing equipment more efficient, taking some of the workload off your staff. It helps to inform decisions on the brewery floor with data that you can visualise. Our standard automation modules help to capture and conceptualise data, including production analytics, OEE, and downtime. As a result, you can run the brewery more efficiently.