White Paper: Mobile-First UI/UX Design for Control Systems

Discover the difference with CentricPA’s commitment to your plant’s success, developing turnkey solutions to revolutionise manufacturing.

Mobile-First UI/UX Design for Control Systems

Introduction

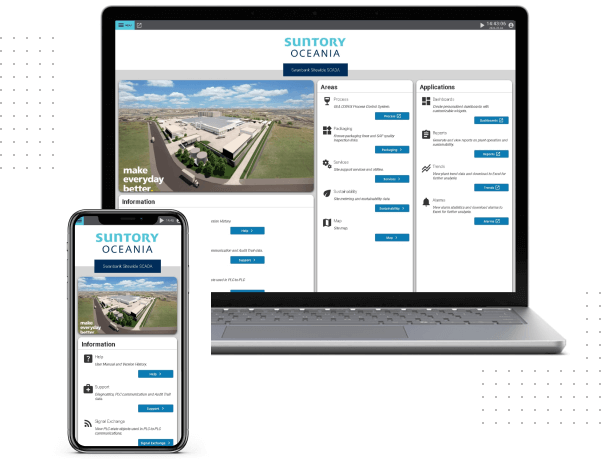

Centric Process Automation (Centric PA) has highlighted a significant need for the customers to have Mobile-First UI/UX Design in their control systems. Mimic based Supervisory Control and Data Acquisition (SCADA) systems are no longer viewed as the best way to display information to the operational and management teams.

Mobile-first design prioritises handheld devices, but also scales up to larger devices seamlessly, this is important as most if not all users will have a mobile device and on average check it 58 times per day. This approach allows users much greater flexibility, efficiency, and accessibility in operating their plant.

Contact our engineering team

Benefits of Mobile-First UI/UX for Control Systems

Enhanced Accessibility

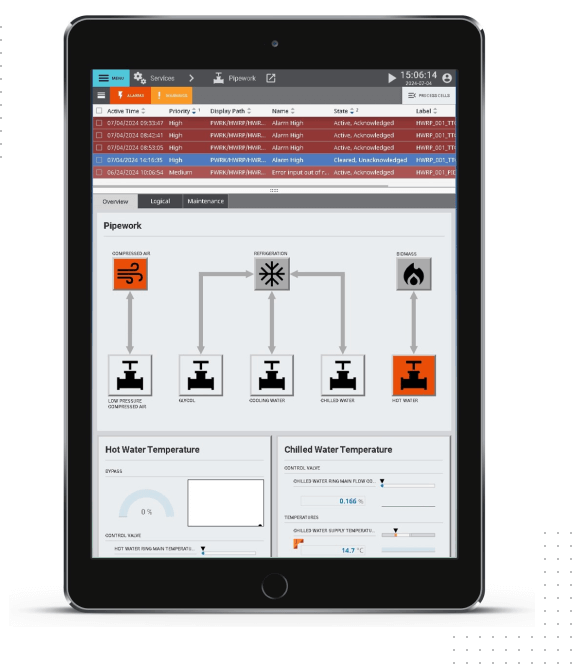

Traditionally plants were operated through desktop terminals that required you to either check the SCADA before or after you went to look at the physical equipment or have someone on the other end of the radio. With mobile-first design operations, maintenance, and management staff can access the SCADA system from portable devices while in the field conducting inspections, tests, commissioning, and many other activities. The ease of access to these systems also makes remote access and control of the plant much easier as you don’t need to have a custom machine for each remote user.

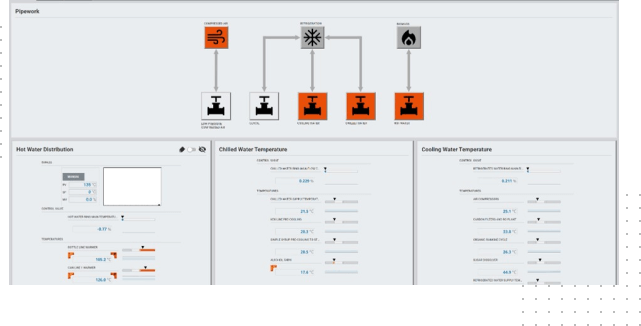

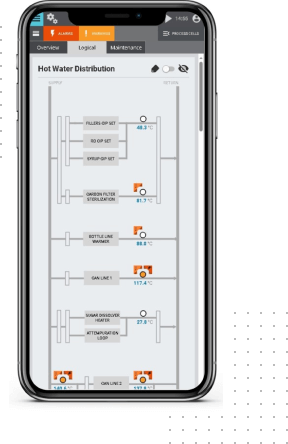

User-Centric Design

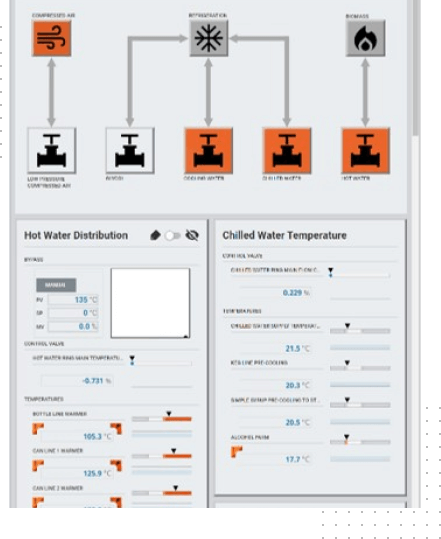

With a focus on ease-of-use mobile-first design offers screens based on the user’s role in the organization, but also focuses on structuring screen via layers of detail. At the highest level an operator’s screen should show them if their plant area is operating correctly and start new operations, if the plant is not operating correctly then it should guide them to more detailed screens for troubleshooting faults. A manager’s top-level screen may contain per line OEE data, number of active issues, etc. while their detailed screens might tell them what line or what shift had the lowest efficiency, so they know where to focus their attention.

Designing for smaller screens prioritizes core functionality resulting in cleaner and more intuitive interfaces. This limits the number of steps required to complete a function and makes operations easier and more efficient.

Scalability

Designing on mobile devices ensures the design is adaptable and scalable in a way that designing for large devices cannot achieve. It is always easier to expand a well-designed mobile screen to larger devices, but often is very difficult to work in reverse.

Improved Real-Time Monitoring

Modern mobile devices already have efficient means for notification of the user, by utilising mobile-first design not only can we notify via the SCADA application, but we can also use systems like Twilio to send messages (emails, SMS, Teams) to users that will then be notified via their mobile device. Designing for smaller screens prioritizes core functionality resulting in cleaner and more intuitive interfaces. This limits the number of steps required to complete a function and makes operations easier and more efficient.Best Practices for Mobile-First UI/UX in Control Systems

Minimalistic and Task-Oriented Design

Mobile-first design focuses on delivering core functionality first and foremost, while also simplifying complex processes. There are many tasks within a plant that can be difficult to execute, but with the correct design can be made simpler and less prone to error.

Responsive Design

It is important to use responsive design techniques for screen size variations even within the mobile device environment. Mobile devices consist of small and large phones, and small and large tablets which can also be used in landscape or portrait orientations, plus in the non-mobile space we have laptops, desktops, and ultra large monitors or TVs. We also have the emerging, market of wearables, virtual reality, and augmented reality that may become more prevalent over time.

Not all devices are equal and can have significant differences in size, resolution, brightness, and other aspects that affect a user’s experience. Correct screen scaling is essential to good design. An example of this would be data that on your phone is displayed vertically in groups or tiles, can then be automatically shuffled to have the groups and tiles in a grid pattern on your laptop or workstation.

Contextual Interactions

Not all users are made equal, some are working at their desk or from home, some are on smart devices in loud factory environments, some may suffer from visual impairments like colour blindness. All these things present unique challenges the mobile-first design techniques can help users to solve.

Streamlined Navigation

It is important that all users can navigate the system effectively using mouse and keyboard, touchscreen, or other methods. Due to this mobile-first design will focus on gestures and interactions that can be shared across all environments, and where that is not possible have alternatives for each experience.

Screen Prioritisation

The first information anyone should see when logging into a modern SCADA system is the information that is most relevant to them. Not only does each area of the SCADA provide the most critical information, but we provide techniques for users to log directly into the most relevant area for their role.

Testing and Feedback

There is no better test environment than that of the end user interacting with the design. It is critical that before the system goes live people at all levels of the customers organization are given a chance to interact and give feedback on the design.

Conclusion

Our FAQs

CentricPA’s most frequently asked questions.

CentricPA brings a wealth of expertise and a strong track record in delivering automation solutions that improve efficiency, quality, and profitability. Our client-centric approach ensures that we can deliver turnkey solutions that not only meet your current needs but also prepare you for future growth.

We have several primary competencies that allow us to assist our clients. This includes designing structured and scalable systems that maximise operational efficiency. Our specialties include systems adhering to international batch S88/S95 standards for exceptional batch control, with robust recipe management solutions. We also provide feature-rich, mobile-first PLC & SCADA systems that connect to MES to deliver the right data at the right time. With track and trace, it’s easy to monitor your ingredients and processes at all time, and with innovative UI/UX, you can empower your staff to act with the data they have. Finally, we offer secure computing solutions with hybrid cloud for seamless IT and OT system integration.

We serve a wide array of industries, including food and drink, chemical, pharmaceutical, defence and emergency services, manufacturing, and waste. We can combine our engineering expertise with your industry know-how to develop a solution that suits you.

Our recipe management systems, built on open-source software, provide precise, efficient, and error-free results when dealing with various SKUs. They allow you to quickly adapt when the concentration of raw materials varies, integrating seamlessly with MES to eliminate ongoing licensing costs and offer a robust, flexible solution.

We implement best-practice cybersecurity management by utilising on-premises cloud-based storage that protects your data. With a private 4G network and hardware hosted in a Tier IV data centre, our solutions safeguard your operations from potential threats.

We focus on delivering forward-thinking outcomes by designing software with a user-first mindset. Our interfaces present complex information in a clear, simplified manner that allows staff on the plant food to collate and interpret data effectively, making quick and informed decisions at crucial moments.