Our Work

CentricPA delivers turnkey solutions to business across sectors. One project, one revolution at a time.Recipe-Based Automation for aRTD Blending

Recipe-Based Automation

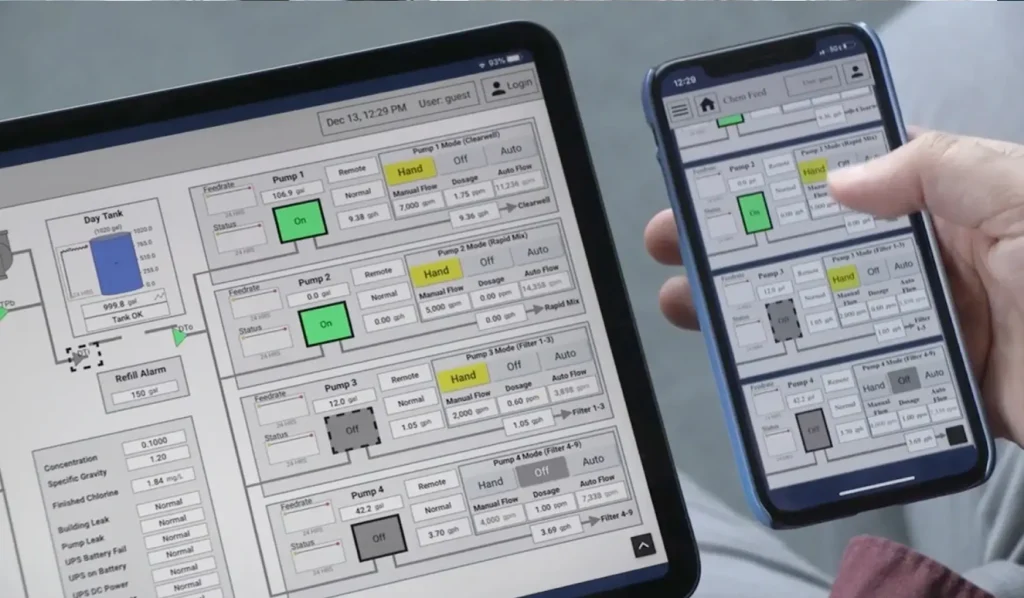

CentricPA’s MES suite features a Recipe Management module with Batch Procedures that control and orchestrate the process on the plant floor. The aRTD manufacturer can define setpoints for product-specific parameters and assess each recipe with a full audit trail from a web browser or mobile application.

Complete Flexibility

Our customer collaborated closely with us during preliminary designs, ensuring all plant equipment was tagged and grouped according to ISA-88 conventions. As a result, Process Descriptions are efficient, reducing PLC code and saving capital while minimising commissioning windows and risk.

Efficient Implementation

Our software library of standard modules ensured that the aRTD plant could optimise the equipment it already had, from PID controllers to valves. Thanks to a feature-rich automation system, the customer had complete control over the process with a solution that works ‘out of the box.’

Enhanced Operational Efficiency

Our specialised approach ensured that the aRTD plant had complete control, benefitting from advanced features that improved efficiency, reduced risk, and enhanced overall operational efficiency.

Top line results

+150%

Increase revenue

Total Sale

The Brand

aRTD beverages are experiencing tremendous industry growth, with supplier revenue rising by 42% in 2021. It’s difficult for brands in this industry to stand out, but they can attempt to garner favour with consumers through consistent products that taste great and deliver the same enjoyable flavour every time.

In working closely with an aRTD blending plant, CentricPA leveraged our deep understanding of process automation to enhance their production methods, allowing for specific quantities of alcohol, sugar mass, and water in each product, as well as minimum and maximum batch sizes. Plus, the system automatically accounts for variations in raw material concentration (ABV%, Simple Syrup Brix) and adjusts nominal setpoints accordingly.

As a result, the products emerging from this plant are consistently high quality and allow our client to stand out in an increasingly competitive market.

Challenge

Navigating the difficulties of aRTD liquid processing

Getting the quantities right for consumer beverages can be tricky, especially where alcohol is concerned. CentricPA thrives on tackling complex manufacturing challenges such as this, where variations in the raw ingredients and the need for precision control are paramount.

Approach

A tailored approach to automation

Our unique approach begins with a deep understanding of the customer’s specific requirements and goals. We embraced this challenge with a customer-centric mindset, providing tailored solutions that aligned seamlessly with their manufacturing processes.

Solutions

Finding the path to quality

CentricPA’s expert engineers designed an advanced automation system, harnessing the power of our recipe management module. We incorporated brand-specific parameters so that the client can meet their requirements with precision, enabling flexibility and real-time adjustments. Our approach incorporated industry best practices, ISA-88 conventions, and modular automation to guarantee an efficient, reliable solution.

Results

Elevating precision for aRTD beverages

The results were transformative. The blending plant now has a cutting-edge automation system that enhances production quality and the capacity to adapt swiftly. This ensures that the client can meet the parameters for a blended ABV of <24% by controlling the flow rates of each ingredient stream, even when raw material concentration differs.